Semiconductor fabs aim to have high yields and provide processes that attract design firms and win new design starts, but how does a fab deliver their process nodes in a timely manner without having to run lots of expensive silicon through the line? This is where simulation and TCAD tools come into play, and to learn more about this… Read More

Tag: dtco

Design-Technology Co-Optimization (DTCO) Accelerates Market Readiness of Angstrom-Scale Process Technologies

Design-Technology Co-Optimization (DTCO) has been a foundational concept in semiconductor engineering for years. So, when Synopsys referenced DTCO in their April 2025 press release about enabling Angstrom-scale chip designs on Intel’s 18A and 18A-P process technologies, it may have sounded familiar—almost expected. … Read More

Intel Foundry Delivers!

Now that the dust has settled, I will give you my take on the Intel Foundry event. Some might call me a semiconductor event critic as I have attended hundreds of them over the last 40 years starting with the Design Automation Conference in 1984. Foundry events are my favorite because they really are the pulse of the semiconductor industry,… Read More

SPIE 2023 Buzz – Siemens Aims to Break Down Innovation Barriers by Extending Design Technology Co-Optimization

Preventing the propagation of systematic defects in today’s semiconductor design-to-fabrication process requires many validation, analysis and optimization steps. Tools involved in this process can include design rule checking (DRC), optical proximity correction (OPC) verification, mask writing and wafer printing… Read More

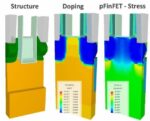

Semiconductor Devices: 3 Tricks to Device Innovation

The semiconductor industry’s incredible juggernaut has been powered by device innovations at its very core. Moreover, present-day enterprises encounter immense competitive pressures and innovations are a key differentiator to maintain their competitive edge1.

“It wasn’t that Microsoft was so brilliant or clever… Read More

IEDM 2022 – Imec 4 Track Cell

At the IEDM conference in December 2022, Imec presented “Semi-damascene Integration of a 2-layer MOL VHV Scaling Booster to Enable 4-track Standard Cells,” I had a chance to not only read the paper and see it presented, but also to interview one of the authors Zsolt Tokie.

Logic designs are built up by standard cells such as inverters,… Read More

Design Technology Co-Optimization for TSMC’s N3HPC Process

TSMC recently held their 10th annual Open Innovation Platform (OIP) Ecosystem Forum. An earlier article summarized the highlights of the keynote presentation from L.C. Lu, TSMC Fellow and Vice-President, Design and Technology Platform, entitled “TSMC and Its Ecosystem for Innovation” (link).

One of the topics that L.C. … Read More

Technology Optimization for Magnetoresistive RAM (STT-MRAM)

Spin-transfer torque magnetoresistive RAM (STT-MRAM) has emerged from several foundries as a very attractive IP option. An introduction to MRAM technology from GLOBALFOUNDRIES was provided in this earlier SemiWiki article. [1]

Briefly, STT-MRAM is a non-volatile storage option with the following attractive characteristics… Read More

Imec Technology Forum and ASML

On Thursday July 9 Imec held a virtual technology forum. Imec is one of the premier research organizations working on semiconductor technology and their forums are always interesting. My area of interest is process technology and the following are my observation in that area from the forum.

Luc Van Den Hove

Luc Van Den Hove is the… Read More

TSMC’s 5nm 0.021um2 SRAM Cell Using EUV and High Mobility Channel with Write Assist at ISSCC2020

Technological leadership has long been key to TSMC’s success and they are following up their leadership development of 5nm with the world’s smallest SRAM cell at 0.021um 2 with circuit design details of their write assist techniques necessary to achieve the full potential of this revolutionary technology. In addition to their… Read More